Selected Projects

Bridging the gap between OT and IT. A collection of industrial automation, IIoT, and embedded systems engineering projects.

Hybrid Edge-Cloud Architecture

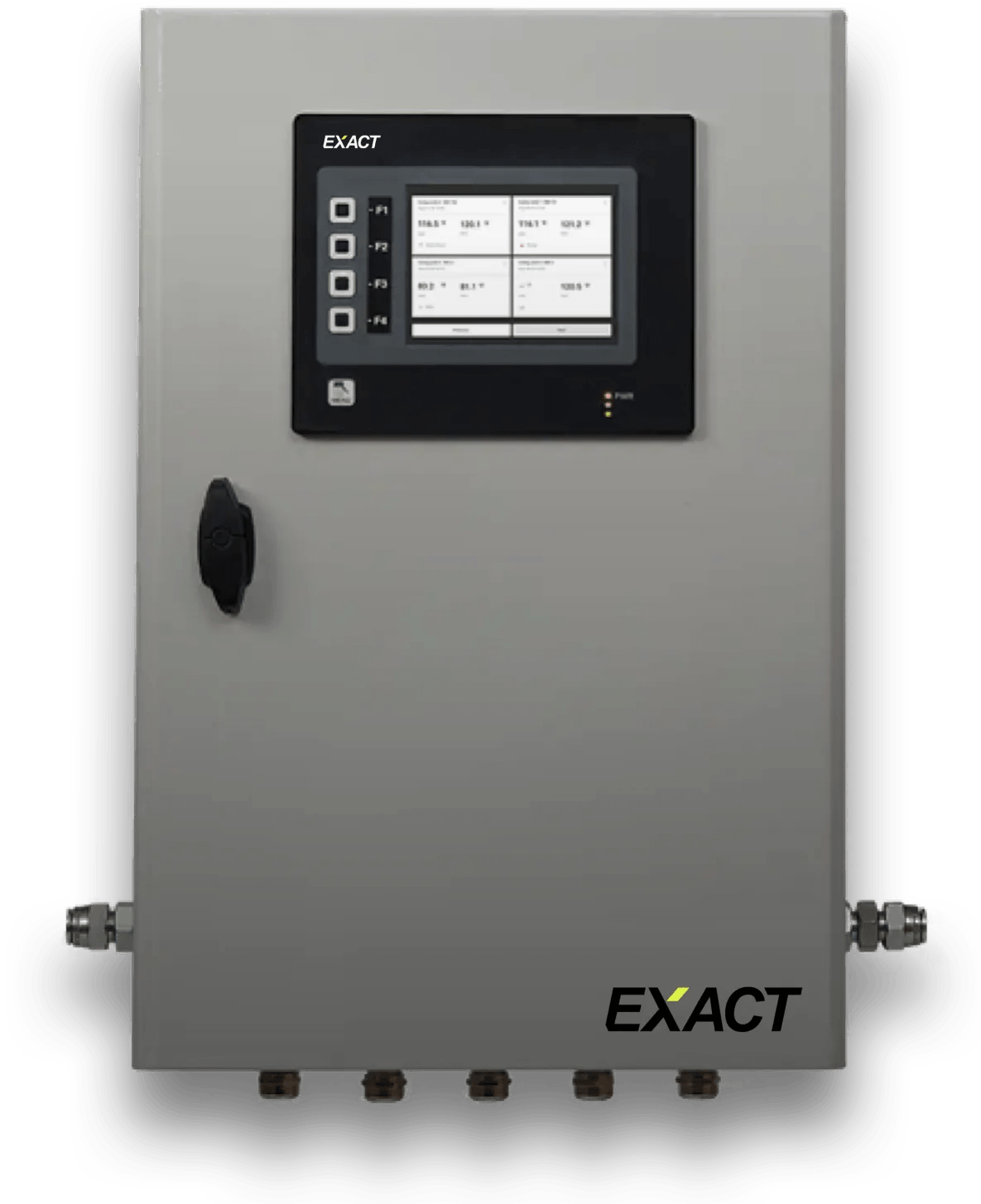

ExactCure: Mission-Critical Control for Precast Concrete

Architected and deployed "ExactCure V4", a control system balancing cloud analytics with absolute local reliability. Designed a Hybrid Edge Architecture combining an ABB PLC with an Industrial Raspberry Pi.

Challenge

Operations faced the "Connectivity Trap" where internet outages stopped curing cycles, and rigid legacy controllers required rewriting logic for every new plant layout.

Solution

Implemented a Split-Plane MQTT Architecture. The local ABB PLC and Edge Node handle critical control loops autonomously, while buffering data for AWS IoT Core.

Impact

Achieved 100% local uptime with Zero Data Loss. Scaled deployment to multiple plants using software-defined configuration files instead of hard-coded logic.

High-Performance Edge Gateway

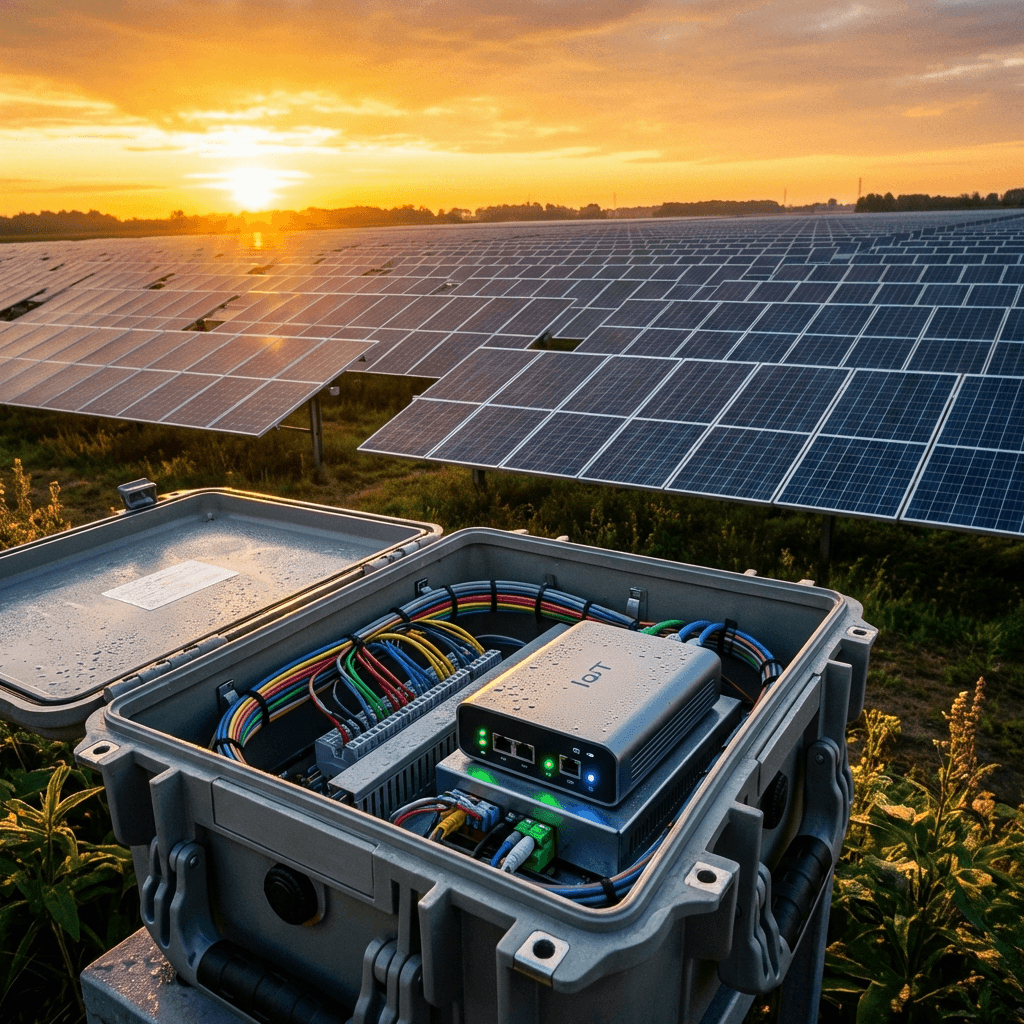

639 Solar: SNMP-to-MQTT Bridge for Datacenters

Engineered a production-grade edge gateway to integrate legacy Sentry PDUs with a modern Ignition SCADA system via MQTT, reducing latency from minutes to sub-seconds.

Challenge

Bridging the protocol gap between synchronous, polling-based SNMP v2c devices and a real-time Unified Namespace (UNS) architecture without blocking operations.

Solution

Built an Asyncio Python gateway that fires parallel SNMP requests and publishes normalized JSON payloads to MQTT. Includes intelligent aggregation for daisy-chained units.

Impact

Unified legacy PDU data with modern solar telemetry in a single pane of glass. Enabled reactive alarming via UDP Trap listening.

Industrial Protocol Normalization

WAGO IIoT Gateway: Unifying Field Operations

Designed a "Local Brain" using a WAGO PFC200 to normalize heterogeneous field signals (Analog, RS-485, Digital) into a standardized Modbus TCP interface for SCADA/BMS.

Challenge

Managing a "Babel Tower" of field devices (4-20mA, Modbus RTU, Discrete) created signal chaos and bus collisions on a single RS-485 line.

Solution

Implemented a deterministic State Machine Sequencer in CODESYS to orchestrate polling. Created a self-diagnosing interface that reports signal health alongside values.

Impact

Reduced troubleshooting time by 80% by pinpointing sensor faults (e.g., "Wire Break") directly in the SCADA tag registers.

Safety Systems Engineering

Mitsubishi PLC Rescue: Refactoring Obfuscated Logic

Performed a complete reverse engineering and clean rewrite of a obfuscated OEM codebase for an imported manufacturing machine to meet local safety compliance.

Challenge

The original "Black Box" code was intentionally obfuscated and unsafe. Adding required safety interlocks to such fragile logic posed a severe risk.

Solution

Traced electrical schematics to map I/O and rewrote the logic using a clean State Machine architecture. Separated Safety logic from Process logic.

Impact

Achieved full safety compliance and vendor independence. The client now owns a documented, maintainable codebase.

Secure Remote Control

Secure Edge Gateway: Bi-Directional PLC-to-Cloud

Engineered a lightweight Node-RED gateway to bridge critical process PLCs with cloud SCADA. Implemented secure bi-directional control with Store-and-Forward capabilities.

Challenge

Enabling remote control over the internet without exposing the PLC to security risks, while handling frequent network micro-outages.

Solution

Deployed a Node-RED gateway acting as a secure proxy. Implemented a local SQLite buffer to cache data during outages and burst-sync upon reconnection.

Impact

100% Data Completeness in historic charts and secure, operational agility for remote plant managers.

Precision Process Control

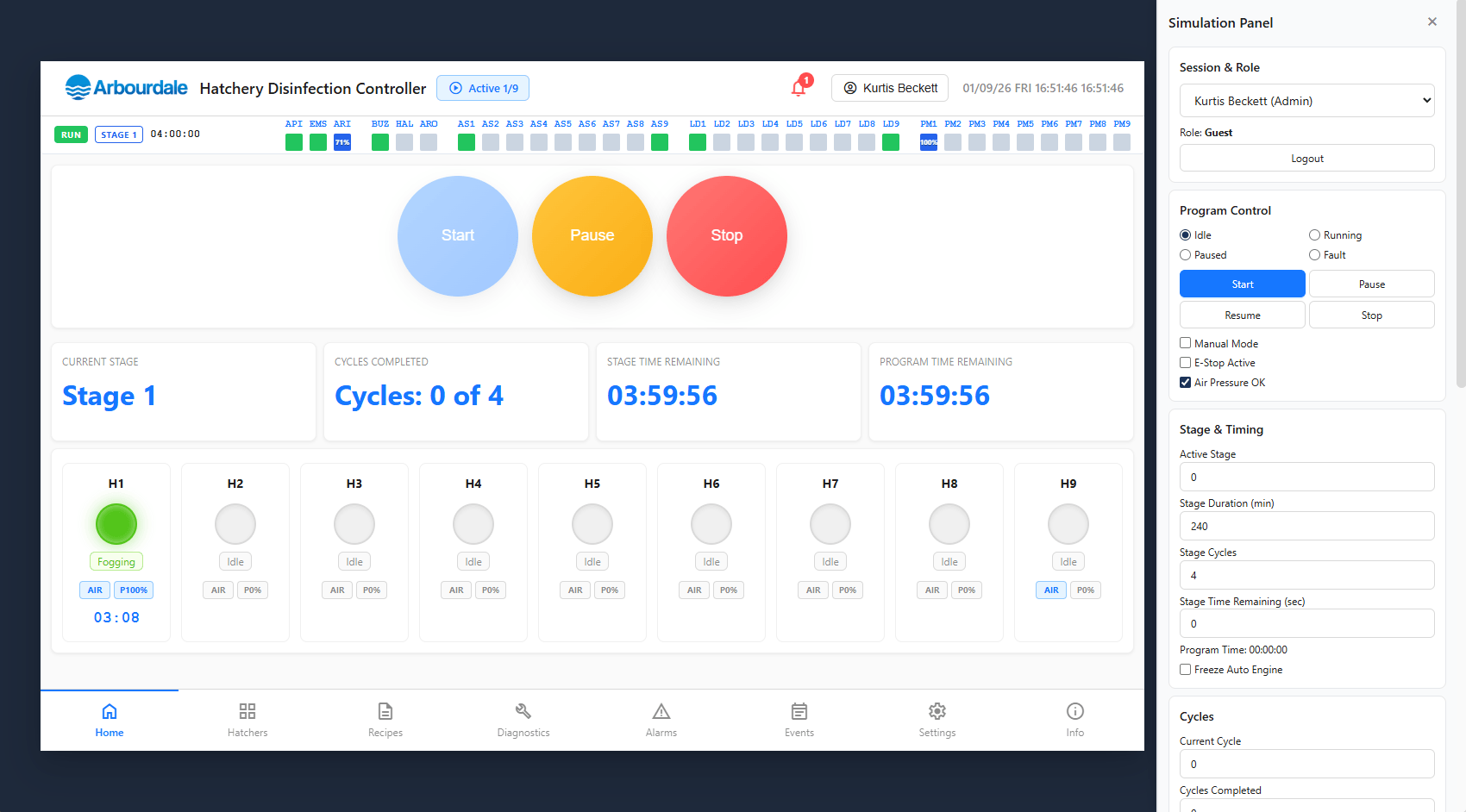

Hatchery Fogger: Simulation-First PLC Workflow

Designed a turnkey disinfection control system for poultry hatcheries using a "Simulation-First" approach to validate logic before hardware deployment.

Challenge

Biosecurity demands extreme precision. Over-dosing kills embryos; under-dosing causes contamination. Standard PWM was insufficient for low-flow pumps.

Solution

Developed a custom Pulse Frequency Modulation (PFM) block on an Arduino Opta (PLC) for linear dosing. Validated 100% of logic via a Python Digital Twin.

Impact

Day 1 deployment was 99% bug-free. The system ensures consistent disinfection cycles with verifiable audit trails.

Robotic Fleet Management

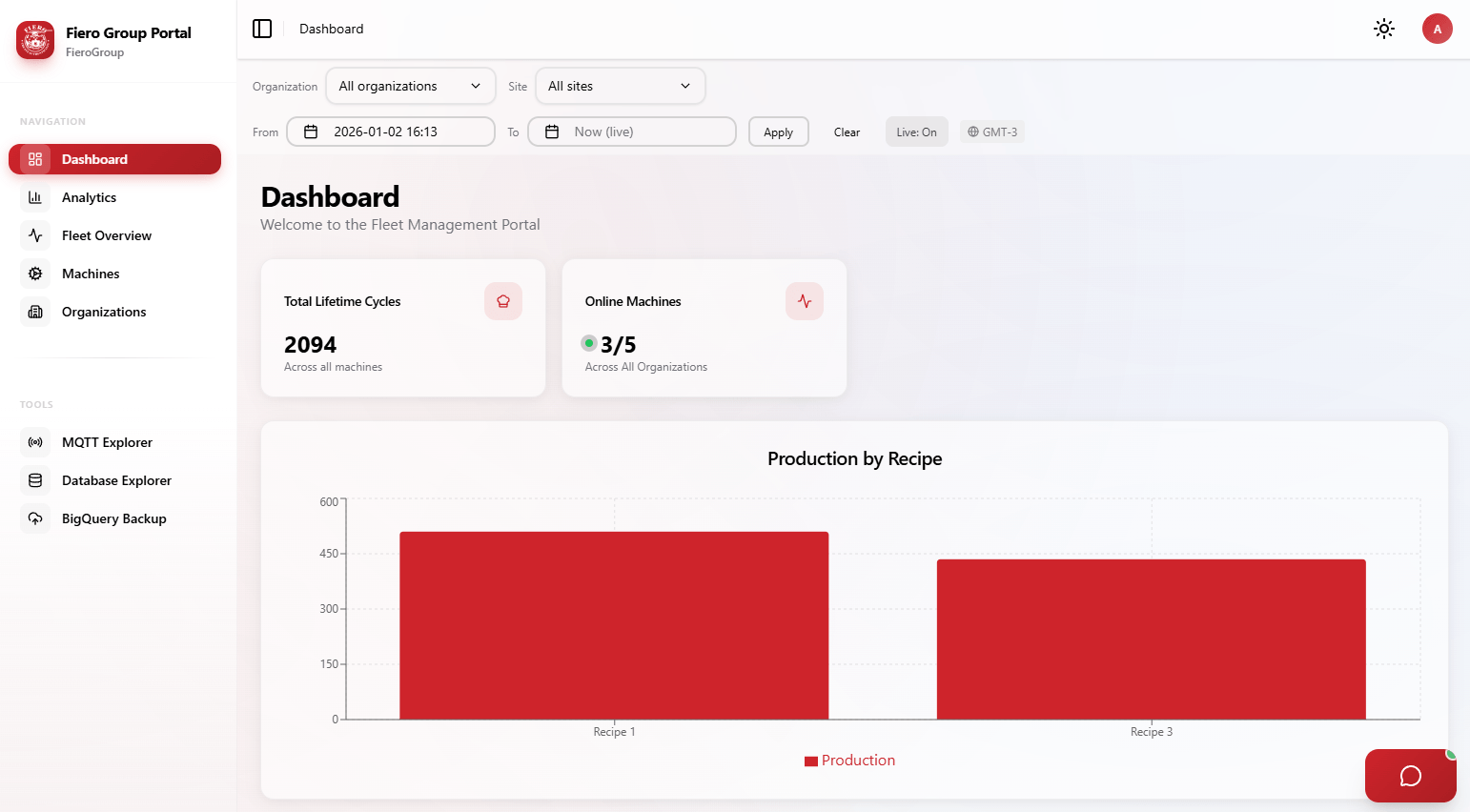

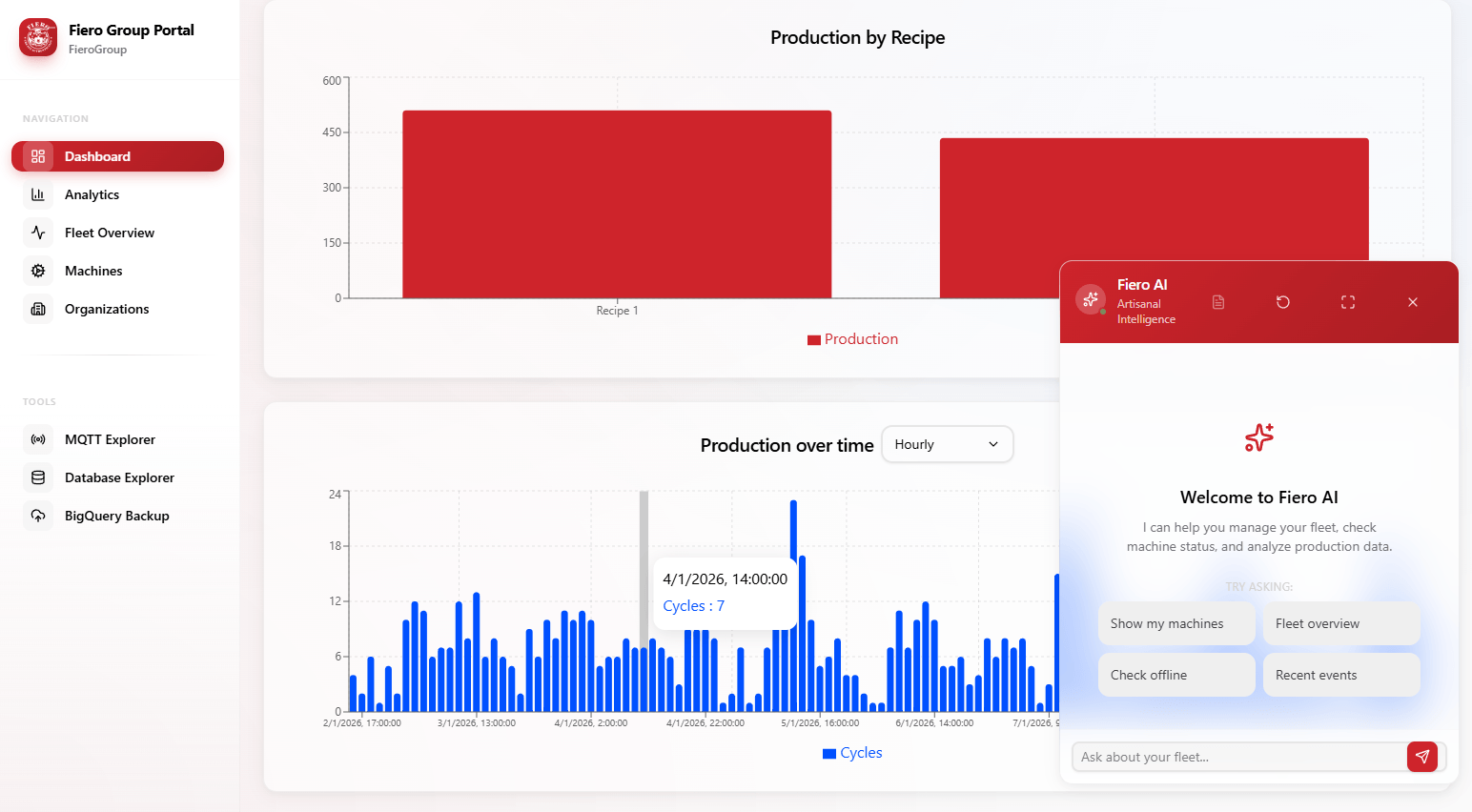

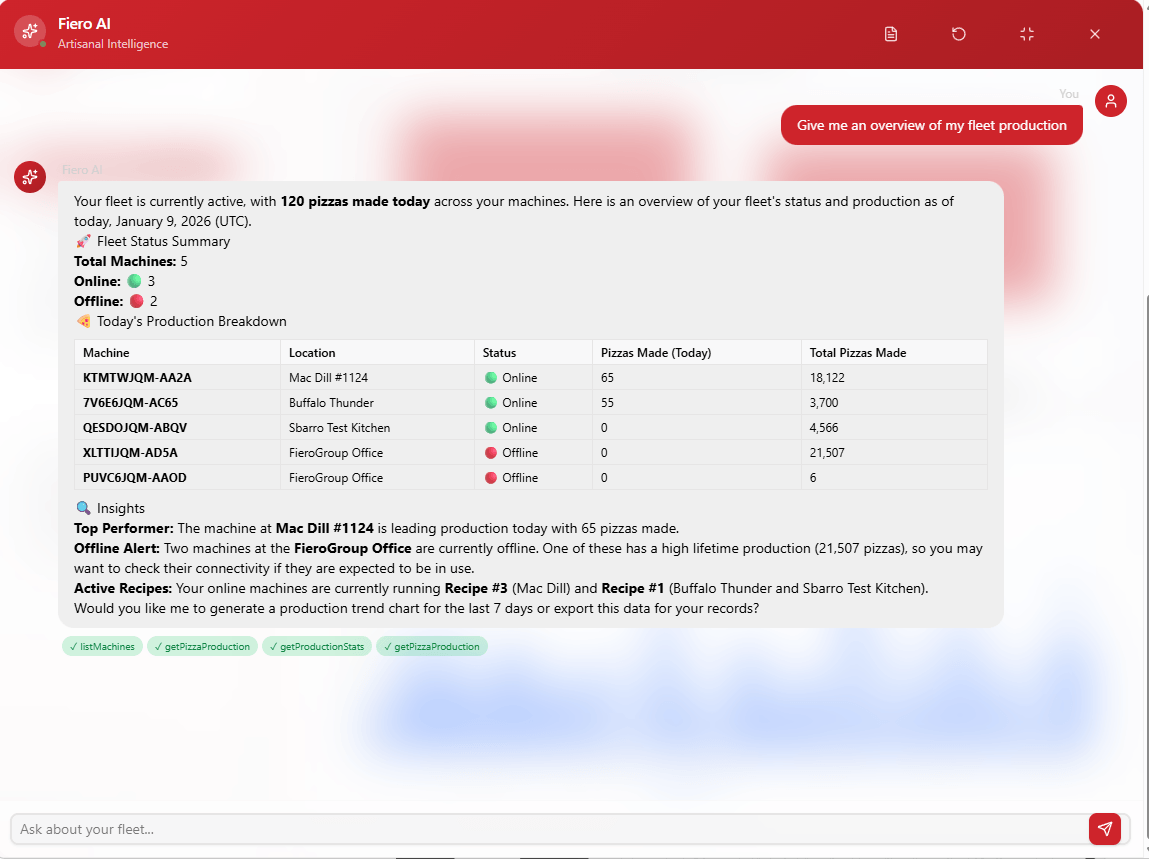

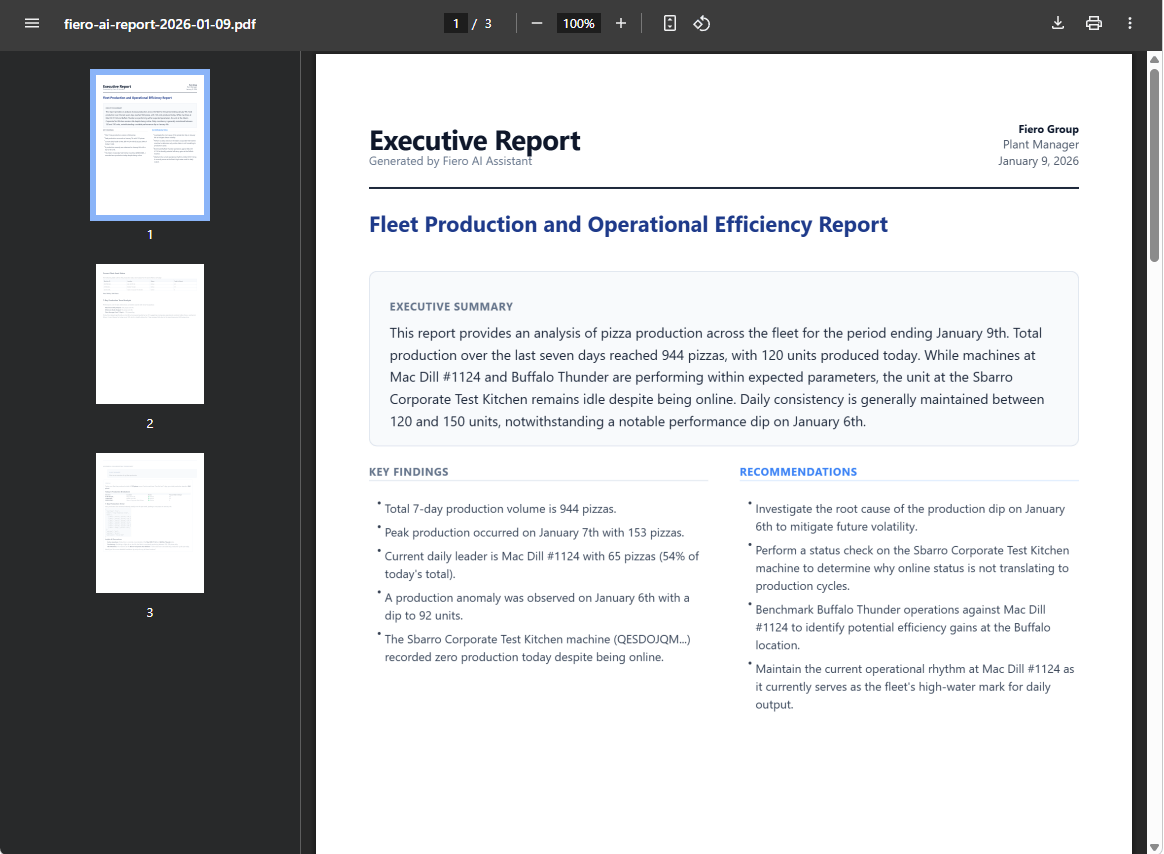

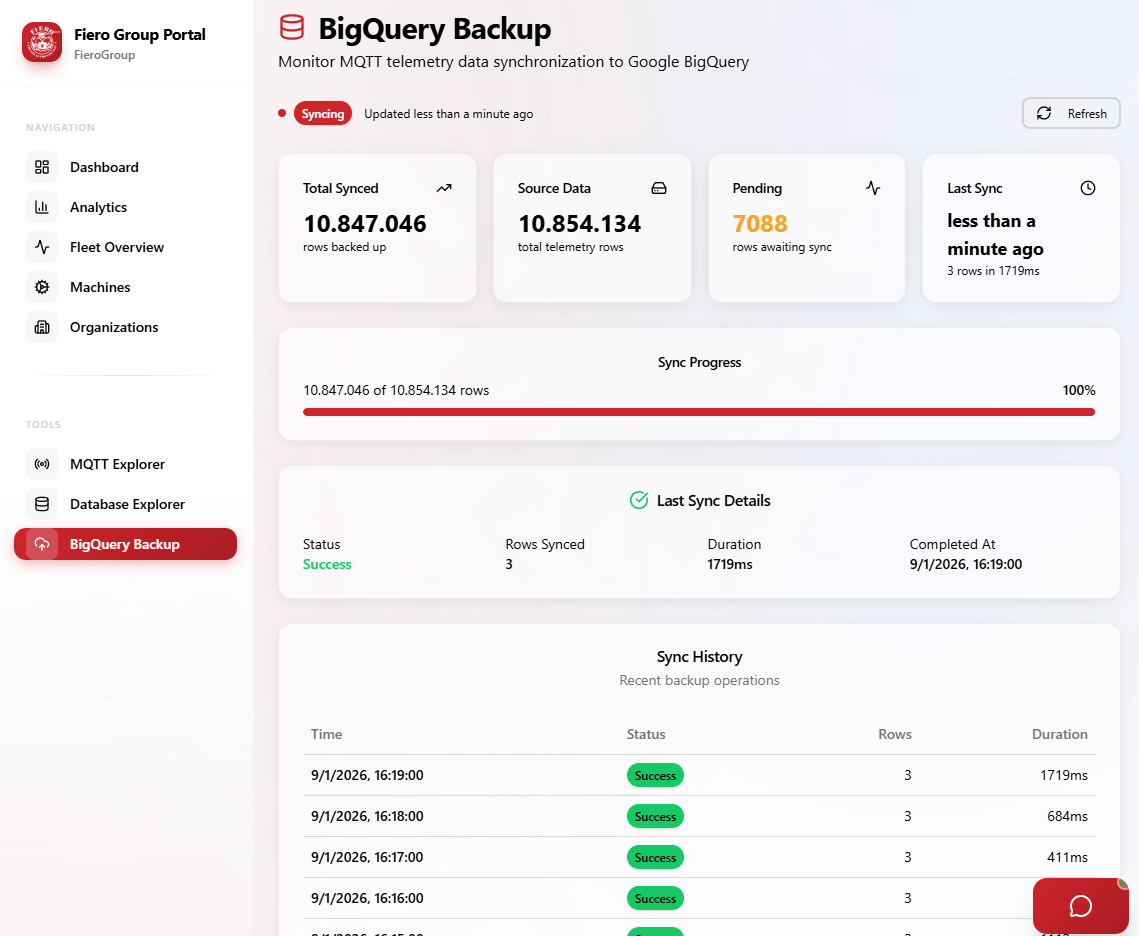

OperaPrima: From Isolated Machines to Cloud Intelligence

Transformed a fleet of standalone robotic pizza machines into a centrally managed IoT ecosystem with real-time telemetry and AI-driven insights.

Project Gallery

Challenge

Machines operated as islands with no visibility into errors or performance. Updates required physical visits, and data was overwritten locally.

Solution

Built a bridge using Weintek HMIs to transmit MQTT data to a Next.js/Supabase cloud. Implemented Row Level Security (RLS) for multi-tenancy.

Impact

Drastically reduced support costs via remote diagnostics and enabled data-driven R&D for future machine iterations.

Open Source Industrial Runtime

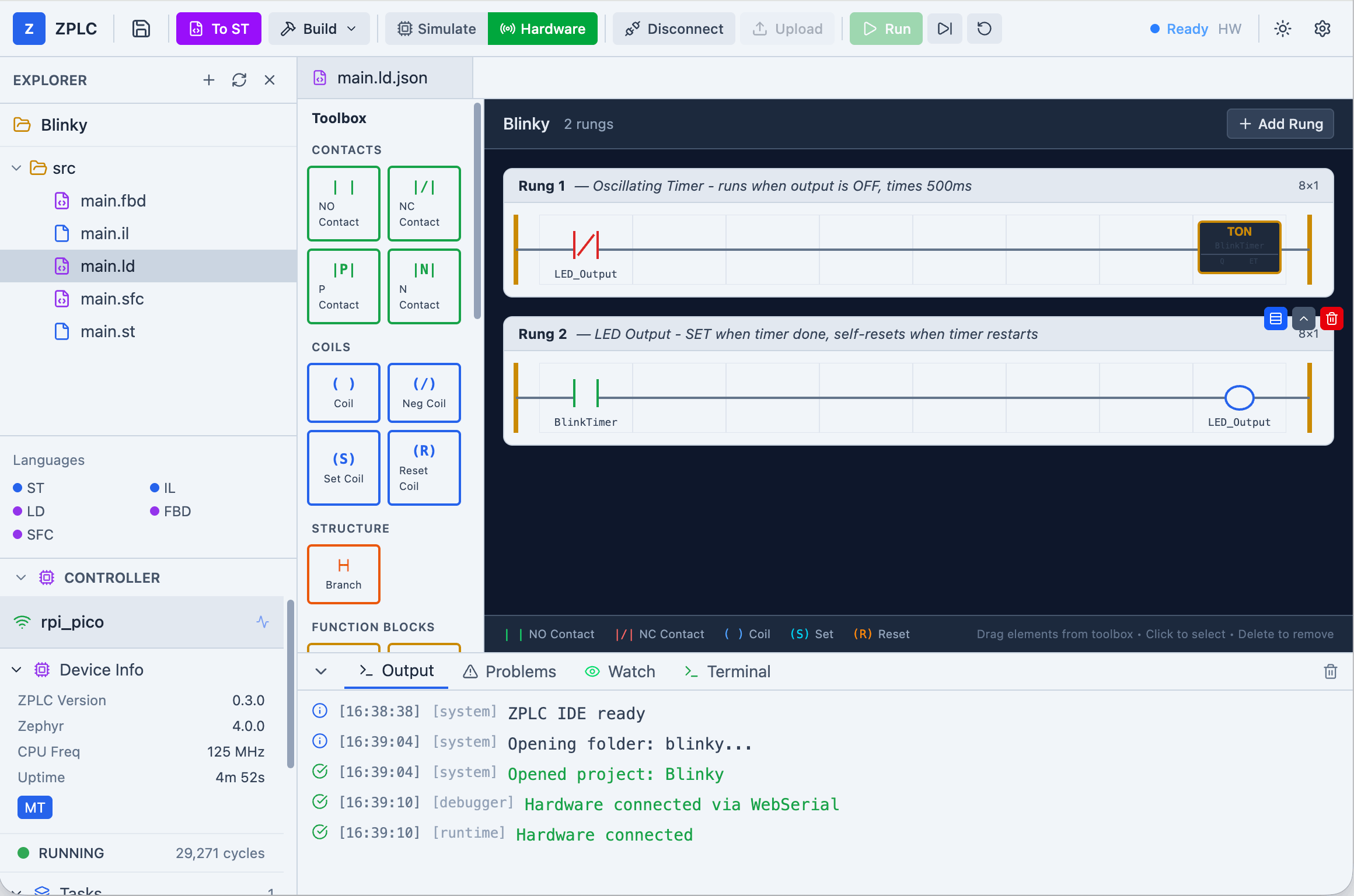

ZPLC: Industrial Control on Commodity Hardware

Designed and built ZPLC, an open-source PLC runtime that transforms cheap microcontrollers (ESP32, STM32) into deterministic industrial controllers.

Challenge

Bridging the gap between the reliability of expensive proprietary PLCs and the flexibility of modern open-source hardware.

Solution

Architected a deterministic Virtual Machine on Zephyr RTOS with a Hardware Abstraction Layer (HAL). Includes a web-based IDE for structured text.

Impact

Democratizes industrial control for SMEs and enables rapid prototyping with a modern, developer-friendly workflow.

High-Performance Driver Development

S7Plus Connector: Native TLS 1.3 for Siemens PLCs

Developed a C++ industrial driver for SIA Connect to communicate natively with modern Siemens S7-1500 PLCs using the encrypted S7CommPlus protocol.

Challenge

Modern Siemens PLCs use non-standard TLS tunneling over COTP. Standard libraries fail to connect, forcing insecure "PUT/GET" workarounds.

Solution

Engineered a custom OpenSSL Memory BIO implementation to wrap TLS 1.3 frames inside ISO-on-TCP packets. Built a symbolic addressing engine.

Impact

Enables secure, high-performance data extraction from Protection Level 3/4 PLCs without compromising plant security policies.

Ready to modernize your operations?

From refactoring legacy PLC logic to building cloud-native IIoT architectures, I help you build robust, scalable systems.