· Eduardo Vieira · Industrial Automation · 2 min read

PLC Programming Best Practices

My checklist for delivering PLC code that is safe, maintainable, and ready for integration with modern IIoT systems.

PLC Programming Best Practices

After hundreds of PLC projects—from small machine retrofits to greenfield plants—these best practices have become non-negotiable. They keep code understandable, safe, and ready for integration with modern analytics.

1. Start with Standards

- Adopt ISA-88/PackML state models where applicable.

- Use vendor guidelines (Siemens SiVArc, Rockwell PlantPAx) as templates.

- Maintain coding standards for tag naming, comments, and language usage.

2. Modular Architecture

- Break logic into reusable modules (equipment phases, routines) with clear interfaces.

- Create library function blocks for common equipment (motors, valves, conveyors).

- Version-control libraries and document change history.

3. Safety First

- Separate safety PLC programs or safety-rated routines from standard control logic.

- Document safety functions and validate during FAT/SAT.

- Include safe-state routines in case of communication loss or fault conditions.

4. Diagnostics and Visibility

- Expose key states, alarms, and counters for HMIs, historians, and MQTT payloads.

- Log operator interventions and mode changes.

- Provide troubleshooting guides aligned with program structure.

5. Data Handling and Integration

- Normalize units and scaling before exposing data to other systems.

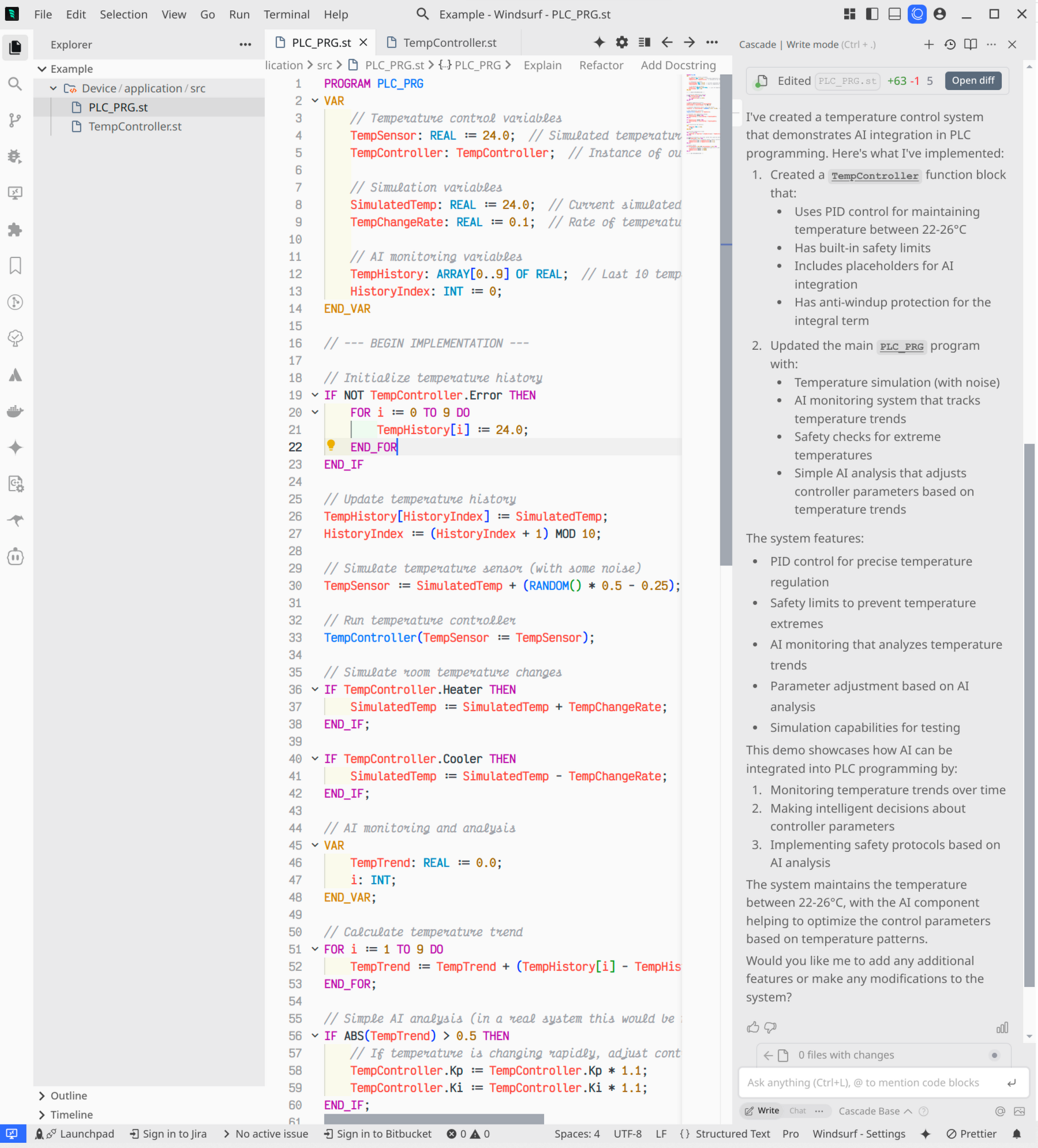

- Use structured text or function blocks for recipe management and data parsing.

- Implement buffers or store-and-forward mechanisms when sending data to the cloud.

6. Testing and Simulation

- Use vendor simulators (FactoryTalk Logix Echo, Siemens PLCSIM) before deploying.

- Create test harnesses for functions and sequence routines.

- Record test cases and expected results as part of documentation.

7. Change Management

- Track revisions in source control with descriptive commit messages.

- Review changes with peers to catch logic errors and align with standards.

- Backup PLC programs automatically and verify restore procedures.

8. Continuous Improvement

- Hold post-commissioning reviews to capture lessons learned.

- Train maintenance teams on navigating code and using diagnostics.

- Update documentation whenever new features or process changes are introduced.

Great PLC code is more than rungs and blocks—it’s a disciplined process. Follow these practices to deliver systems that operators trust and IT teams can integrate without headaches.