· Eduardo Vieira · Strategy · 3 min read

The IT/OT Convergence: A Survival Guide for Industrial Leaders

Why the merger of Information Technology and Operational Technology is inevitable, and how to navigate it without breaking production.

For decades, the factory floor (OT) and the server room (IT) existed in parallel universes. OT prioritized availability and safety—“keep the line running at all costs.” IT prioritized confidentiality and data integrity—“patch everything immediately.”

Today, that separation is a liability. The IT/OT convergence isn’t just a buzzword; it’s the operational reality of 2025. As an architect who has lived on both sides of the air gap, I’ve seen this transition fail more often than it succeeds. Here is why, and how to fix it.

The Friction Point: Data vs. Physics

In IT, a 500ms delay is a “lag spikes.” In OT, it’s a crashed robotic arm or a failed safety stop.

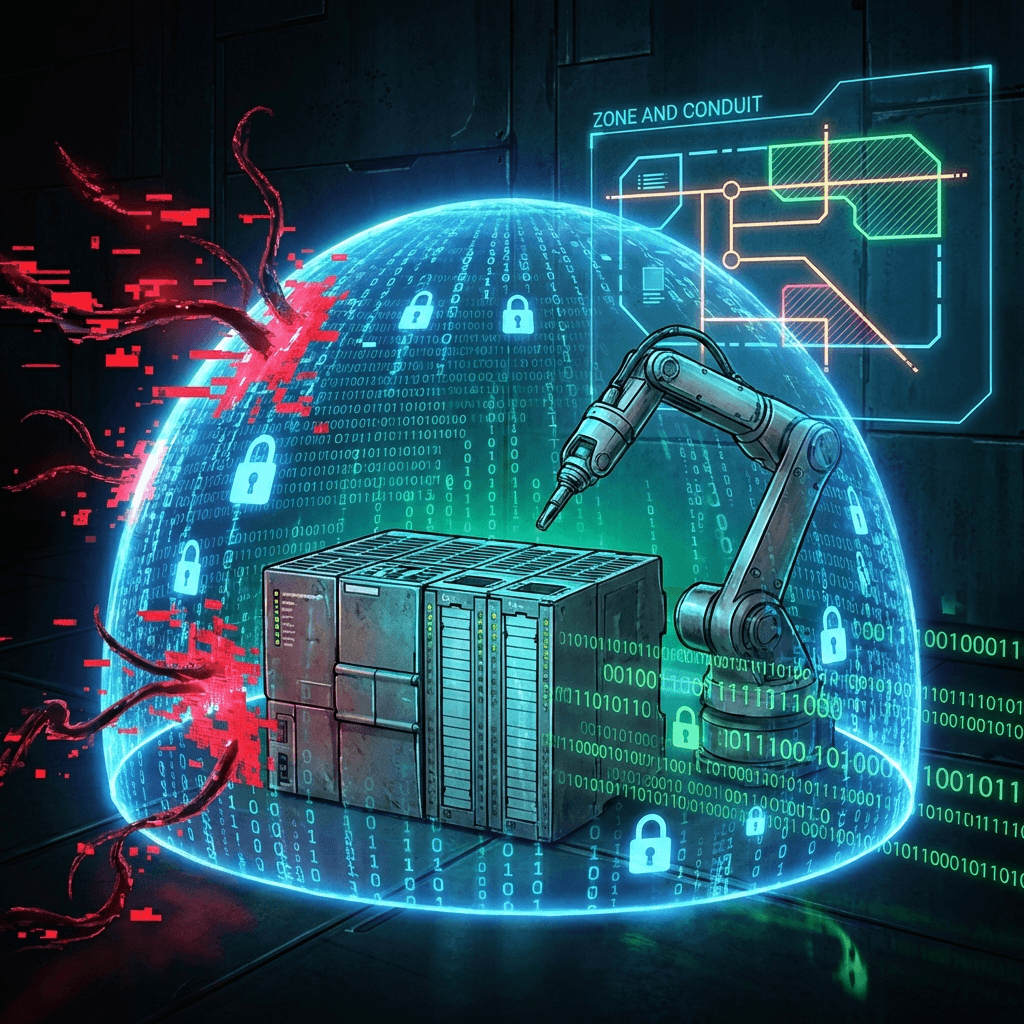

The convergence fails when IT tries to impose enterprise protocols (HTTP, REST) directly onto real-time controllers, or when OT tries to isolate data in proprietary silos (Fieldbus, closed PLCs). The solution lies in the Unified Namespace (UNS) architecture, acting as the demilitarized zone where data meets context.

Key Trends Defining 2025

Recent industry shifts have solidified three pillars regarding this convergence:

- Edgification of Analytics: We no longer send raw sensor data to the cloud. We process vibration analysis at the edge, on the gateway itself, and send only the anomaly alerts to the cloud.

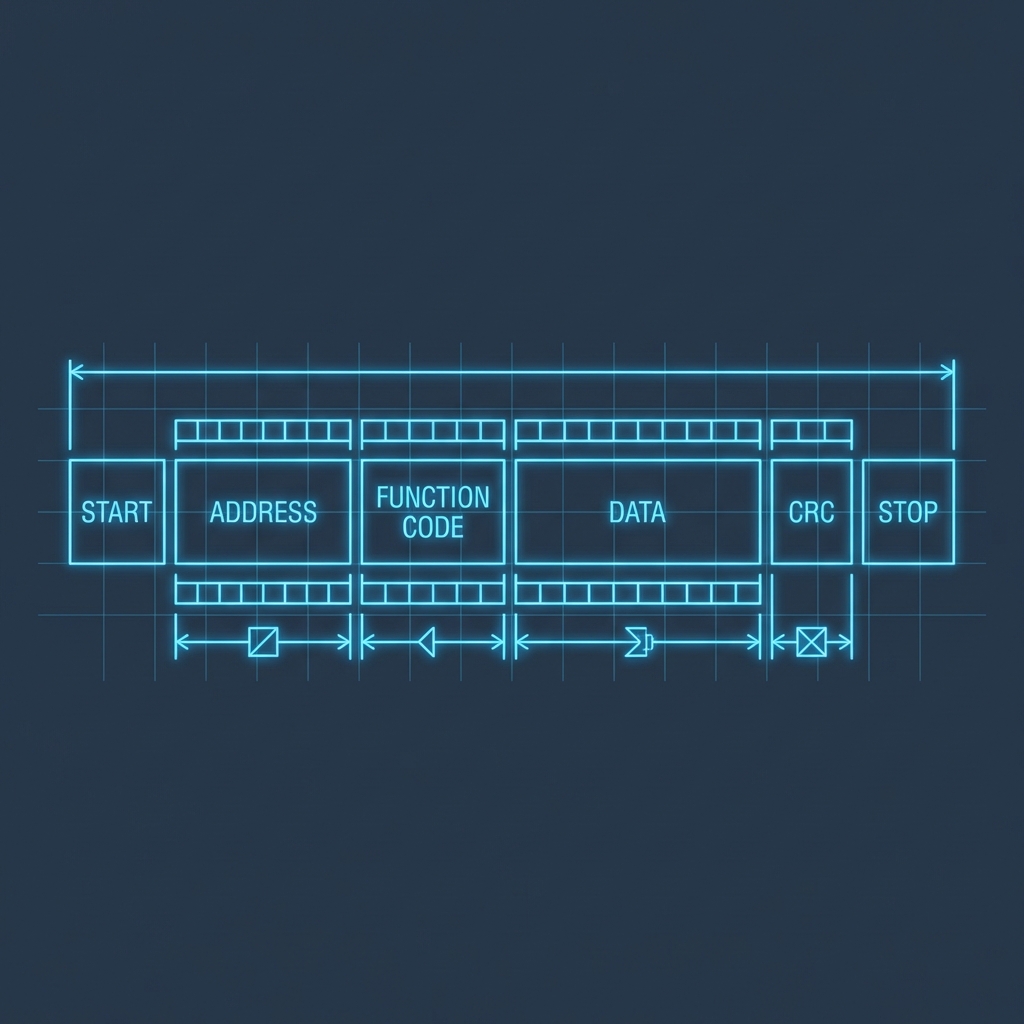

- Security by Design: The “air gap” is dead. Modern OT security relies on Zero Trust architectures, deeper packet inspection for industrial protocols (Modbus, CIP), and unidirectional gateways.

- Data Products over Data Lakes: Instead of dumping terabytes of uncontextualized tags into a data lake, successful plants are building “Data Products”—standardized, ready-to-consume data models for specific assets (e.g., a “Pump Asset Model” that standardizes RPM, Temp, and Vibration across all brands).

How We Bridge the Gap

In my practice, I don’t just “connect” wires. I architect a semantic translation layer.

- We talk IT: REST APIs, GraphQL, MQTT over TLS, Docker containers.

- We talk OT: Modbus TCP, EtherNet/IP, OPC UA, S7 Comm.

By placing an intelligent edge gateway (often running unsung heroes like Node-RED or specialized heavy-lifters like Ignition Edge) between your PLCs and your ERP/Cloud, we ensure that:

- Production is protected: The cloud never polls the PLC directly.

- Data is accessible: Business intelligence tools get clean, JSON-structured data, not raw registers.

The Bottom Line

Converging IT and OT reduces unexpected downtime by enabling predictive maintenance and increases throughput by identifying bottlenecks in real-time. But it requires respect for both disciplines.

Are you struggling to get data out of your legacy machines without risking production stability?

Let’s architect a solution that respects the physics of your plant and the power of your data. Contact me to discuss your industrial transformation.