· Industrial AI · 2 min read

Computer Vision at the Edge: Practical Industrial Implementation Guide

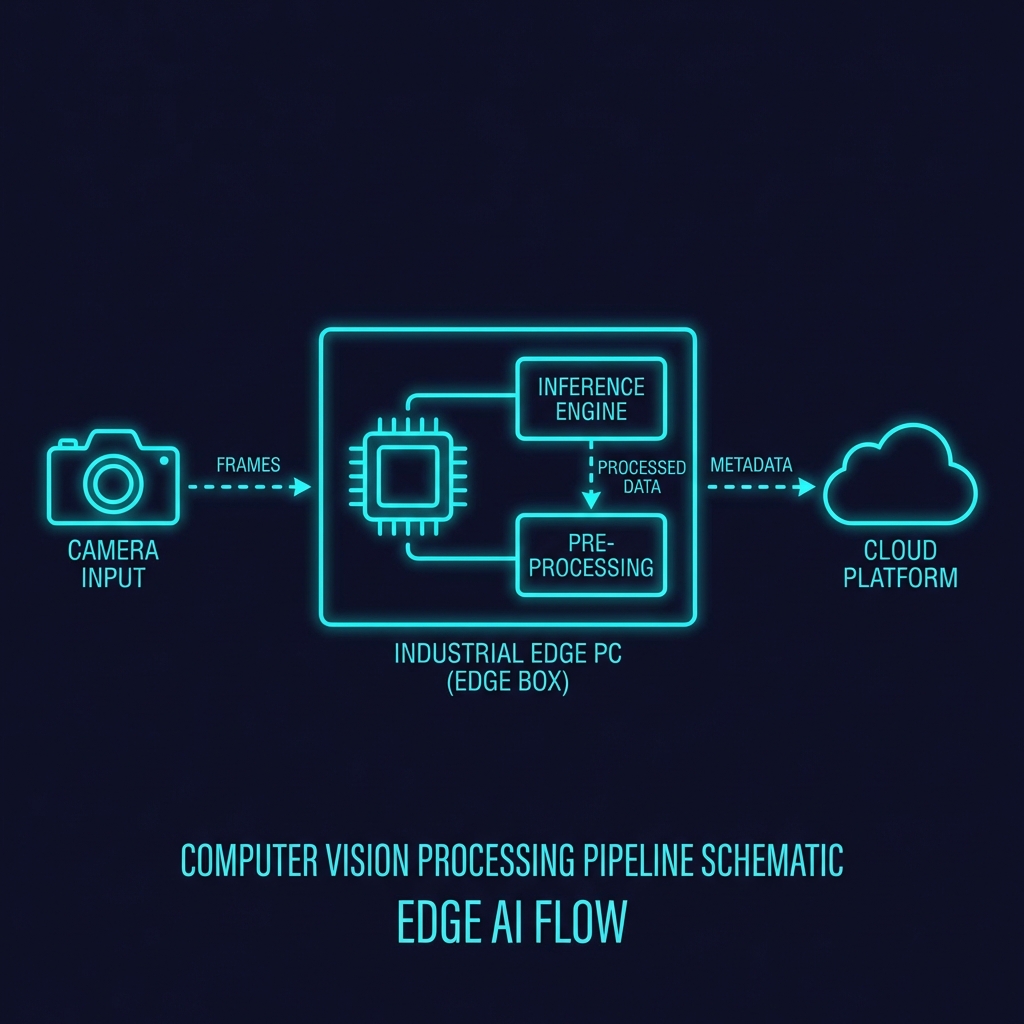

Detecting defects in Python is easy. Telling the PLC to reject the part in 50ms is hard. Guide with YOLOv11, Hailo-8, and Modbus TCP.

The problem with “Artificial Intelligence” in the industry is that 99% of tutorials end when the green box appears around the cat on the screen.

In a real plant, that is useless. If you don’t tell the PLC to reject the part, you just have an expensive TV.

This guide covers the missing link: how to take modern models (YOLOv11) to robust hardware and close the control loop.

1. The Hardware: You Need an Accelerator

A raw Raspberry Pi 5 runs YOLO at 2-3 FPS. Insufficient for a production line. You need an NPU (Neural Processing Unit).

- Hailo-8: The current king of performance/watt. 26 TOPS. Can run multiple HD streams in real-time.

- Google Coral (TPU): Old reliable, but falling short against newer models.

- Nvidia Jetson Orin: The beast. Use if you need pure CUDA, but prepare to pay 10x more.

2025 Recommendation: RPi 5 + Hailo-8L (via M.2 HAT). Total cost < $150 USD.

2. The Model: YOLOv11

Ultralytics just released YOLOv11. It’s lighter and more accurate than v8. Don’t train from scratch. Use Transfer Learning.

- Take 100 photos of YOUR defective parts.

- Label them with CVAT or Roboflow.

- Re-train the base

yolo11n.pt(nano) model for 50 epochs.

3. The Missing Link: OT Integration

This is where data scientists fail. How do you tell the PLC “reject”?

Option A: GPIO (Quick and Dirty)

Wire an RPi pin to a PLC input.

- Pros: Latency < 1ms.

- Cons: Electrical noise, can only transmit 1 bit (YES/NO).

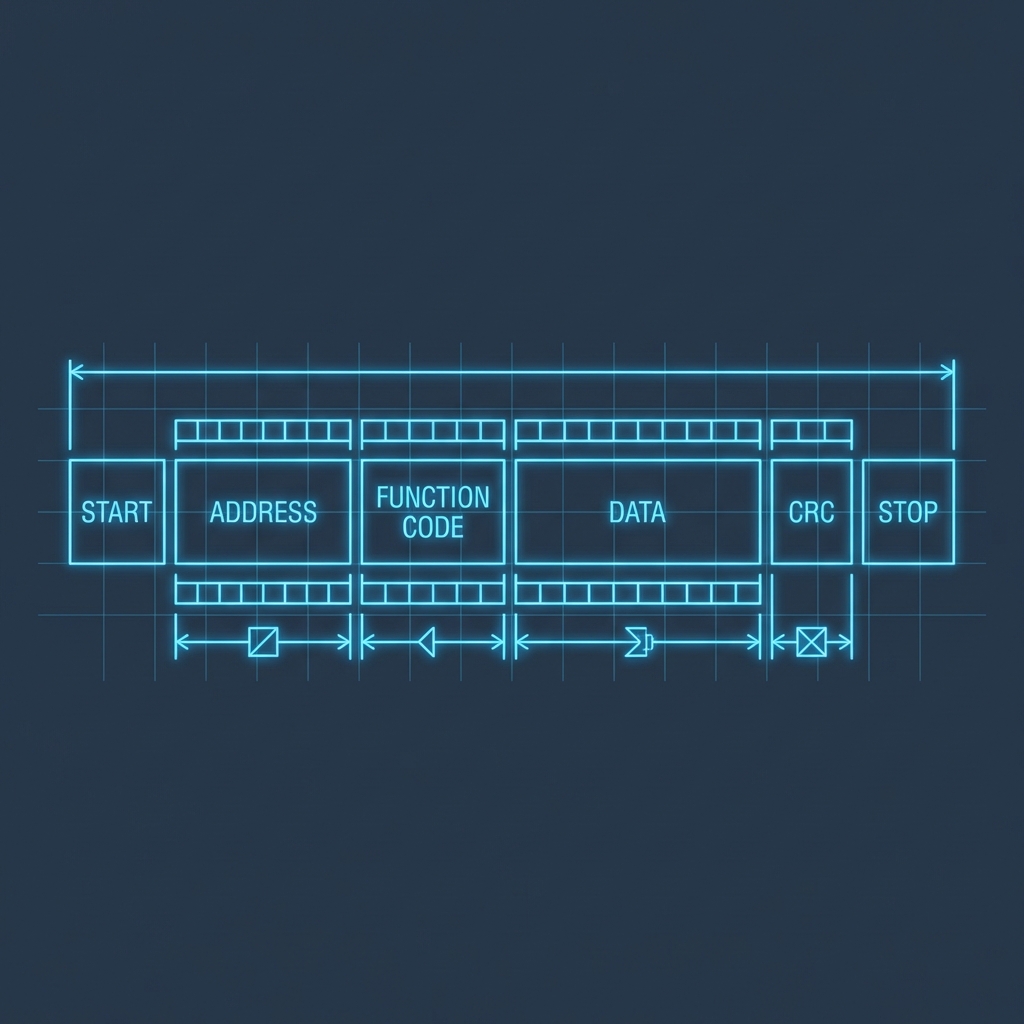

Option B: Modbus TCP (Standard)

Spin up a Modbus client in Python (pymodbus). When defect detected:

# Inference Pseudo-code

results = model(frame)

if user_conf > 0.85:

# Write to PLC Register 40001

client.write_register(1, 1, unit=1)

# Optional: Write X,Y coordinates for a robot to grab it

client.write_register(2, int(box.x), unit=1)4. Latency and Determinism

The PLC expects a response in fixed time. If your neural net takes 200ms sometimes and 50ms others, the PLC will de-synchronize.

- Use GStreamer to capture video without buffering.

- Ensure your inference + communication time is less than the machine’s “Takt Time”.

Conclusion

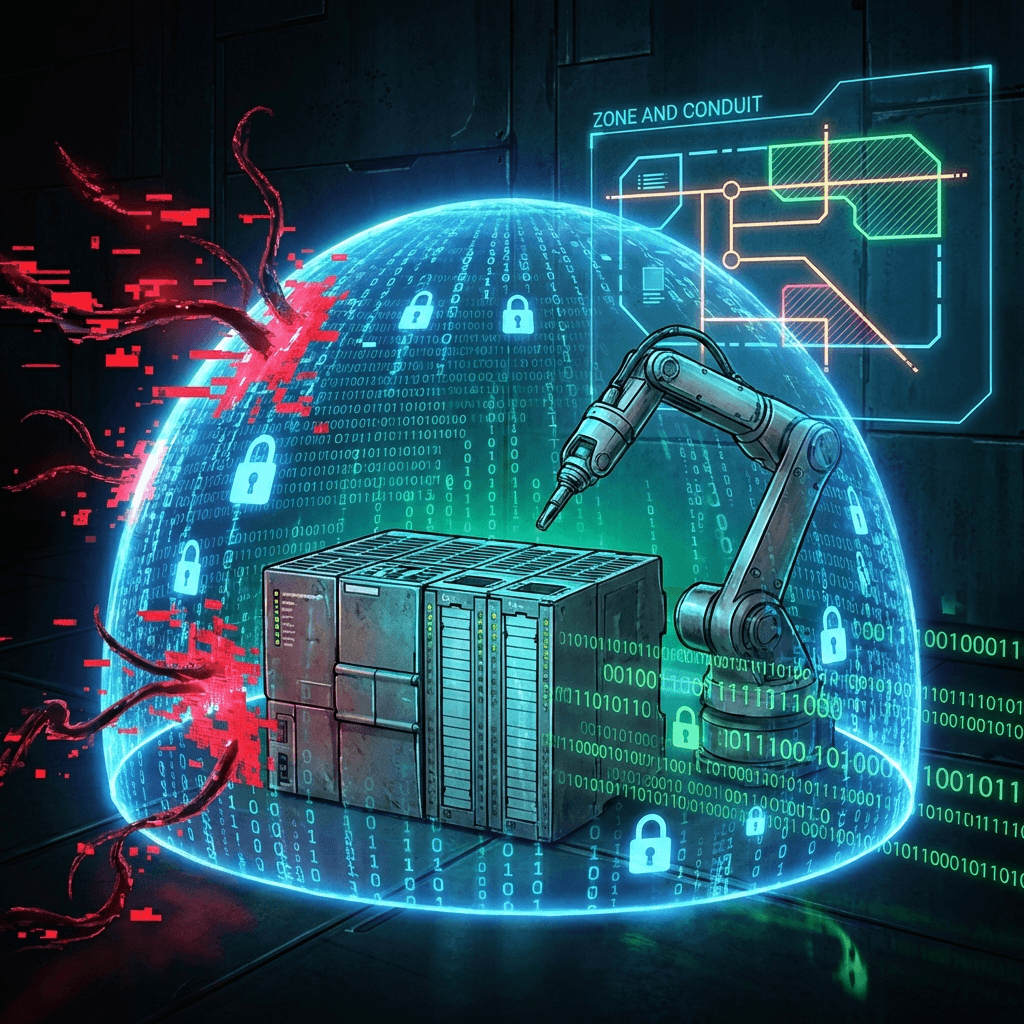

Edge AI is no longer science fiction. With an RPi 5 and a Hailo-8, you have a vision system that competes with $5000 USD smart cameras, but only if you play by industrial rules: robustness, determinism, and standard protocols.